1. Overview

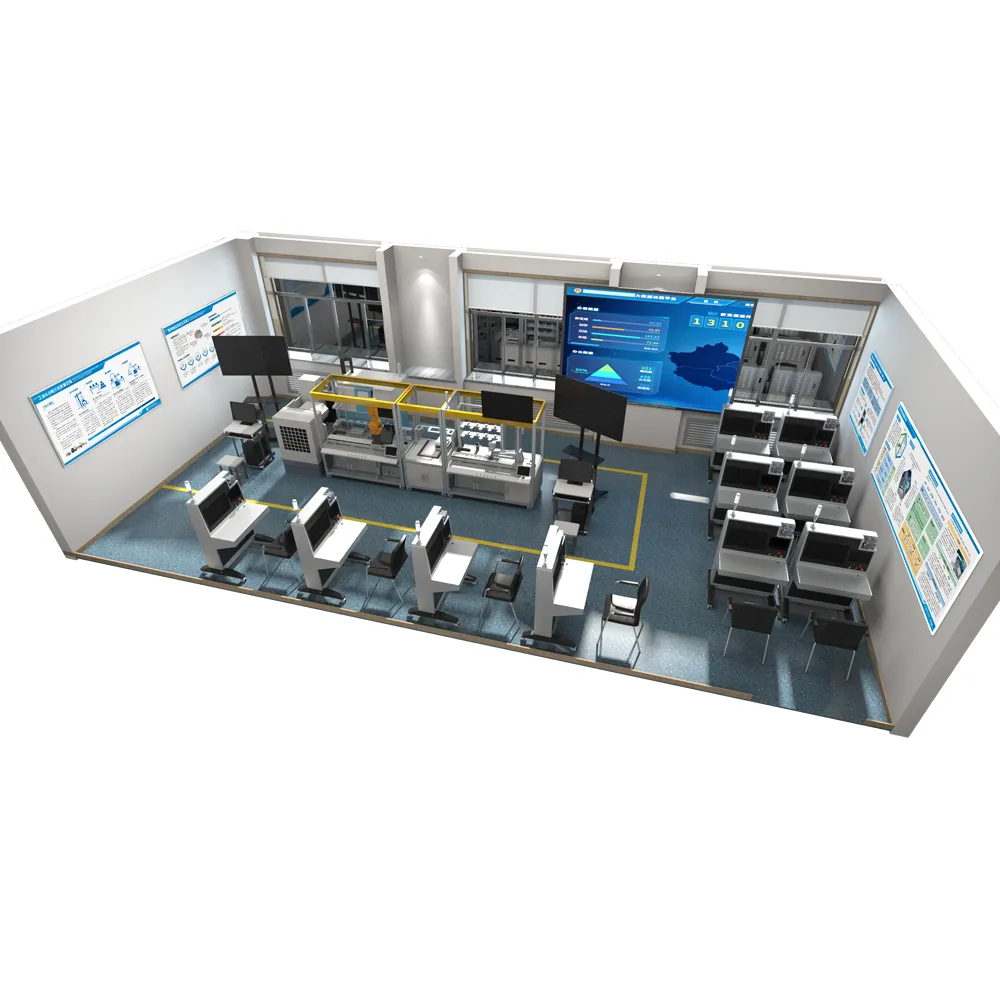

DLIM-441 intelligent manufacturing system integrated application platform mainly includes the following modules: CNC machining unit, intelligent logistics unit, industrial robot unit, and intelligent storage unit. Different combinations such as one-shaped, L-shaped, T-shaped, 㗊(léi)-shaped, etc. can be made according to the site or customer needs.

2. Composition Introduction

The technical engineering lab system is equipped with PLC programming software, touch screen configuration software, robot offline programming, factory automation simulation, MES manufacturing execution, etc. for students to perform programming and virtual simulation debugging

– PLC programming software—Siemens

– Robot offline programming software (optional)

The robot is equipped with KUKA original offline programming software

– MES Manufacturing Execution Management System

– Factory Automation Virtual Simulation Software

Spare list

– 1 set of matching debugging tools for equipment debugging;

– 1 set of supporting tools, including hexagonal wrench, multimeter, flat-head screwdriver, etc.;

– 1 set of air pipes and connectors for supporting equipment, used for installation and debugging of equipment air circuits;

– 16 supporting blanks and 12 workpiece pallets;

……

3. Training Configuration List

| Module name | Components |

|---|---|

| CNC machining station | CNC machining center |

| Fixtures | |

| Online measurement system | |

| Robot station | Robot platform body |

| Handling robot | |

| Robot walking axis | |

| Robot Fixture | |

| Information desk | |

| Industrial Vision Inspection System | |

| Flat storage | |

| Intelligent logistics station | Detection platform body |

| AGV trolley | |

| Turntable | |

| Intelligent storage station | Storage platform body |

| Storage shelves | |

| Three-axis manipulator | |

| Electrical control system | |

| Air supply system | |

| Security | |

| Surveillance system | |

| Touch all-in-one PC and display | |