1. Overview

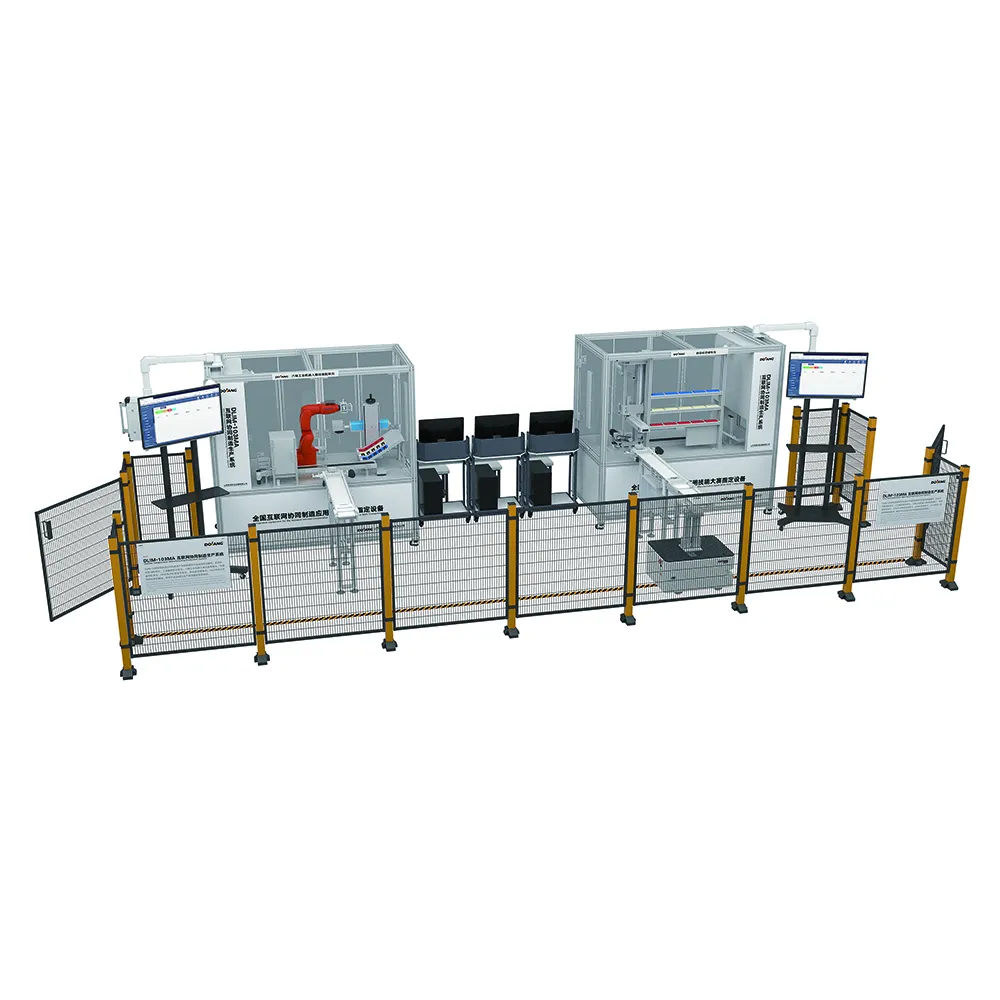

DLIM-103MA Internet collaborative manufacturing production system is produced under the background of new technologies such as the Internet of Things, big data, and artificial intelligence.

The DLIM-103MA vocational education training system hardware platform consists of a network layer kit, a training platform, a bookmark feeding module, an industrial vision inspection module, a six-axis industrial robot handling and assembly module, Bookmark box feeding module, RFID electronic tag reading and writing unit, automatic storage module, AGV mobile car and control system.

The teaching training kits are suitable for training schools, technical colleges, and university labs, such as electrical, electronics, plc, factory automation and mechatronics, and industry robot majors.

2. The main technology of this equipment

1) Sensor detection technology

2) Visual inspection technology

3) Visual dynamic tracking and picking technology

4) Electrical control system

5) Motor drive technology

6) Industrial robot technology

7) Siemens PLC technology

8) Configuration technology

9) Process flow of the production line

10) System maintenance and fault detection technology

11) Digital twin technology

12) MES technology and application

3. Training projects

1) PLC and remote I/O module training experiments

2) Experiments contents between PLC and six-axis industrial robot;

3) Training between PLC and RFID;

4) PLC internet training projects

5) Experiments projects between PLC and AGV trolley;

6) Communication between MES and PLC;

7) Industrial robots install, repair, debug experiments training

8) HMI and servo experiments

9) Experiments of BUS communication technology;

10) Experiments of industrial automation network;

11) Application experiments of PLC technology and motor drive technology;

12) Visual technology, AGV trolley control system, laser marking technology application experiments

13) Digital 3D model knowledge learning experiments and 3D digital production line layout projects

14) PLC virtual commissioning, Off-line programming and debugging of industrial robots

15) MES system learning