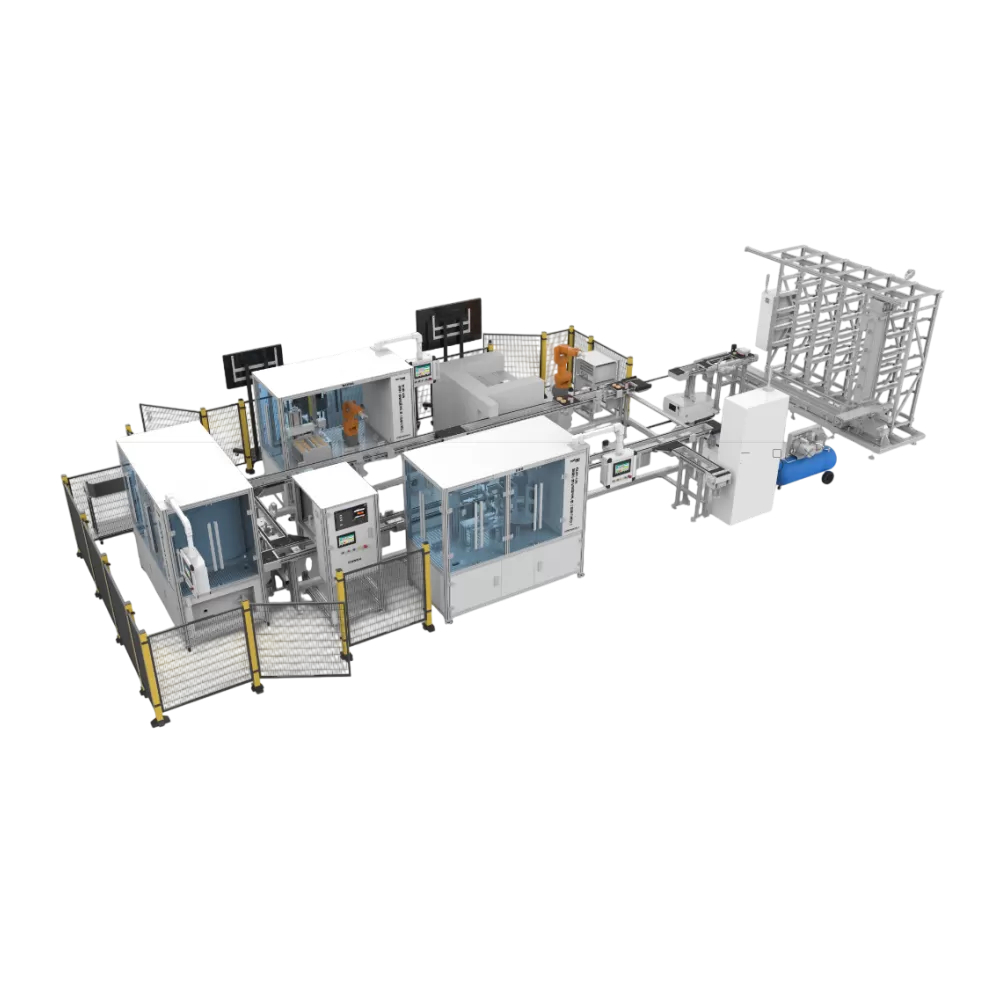

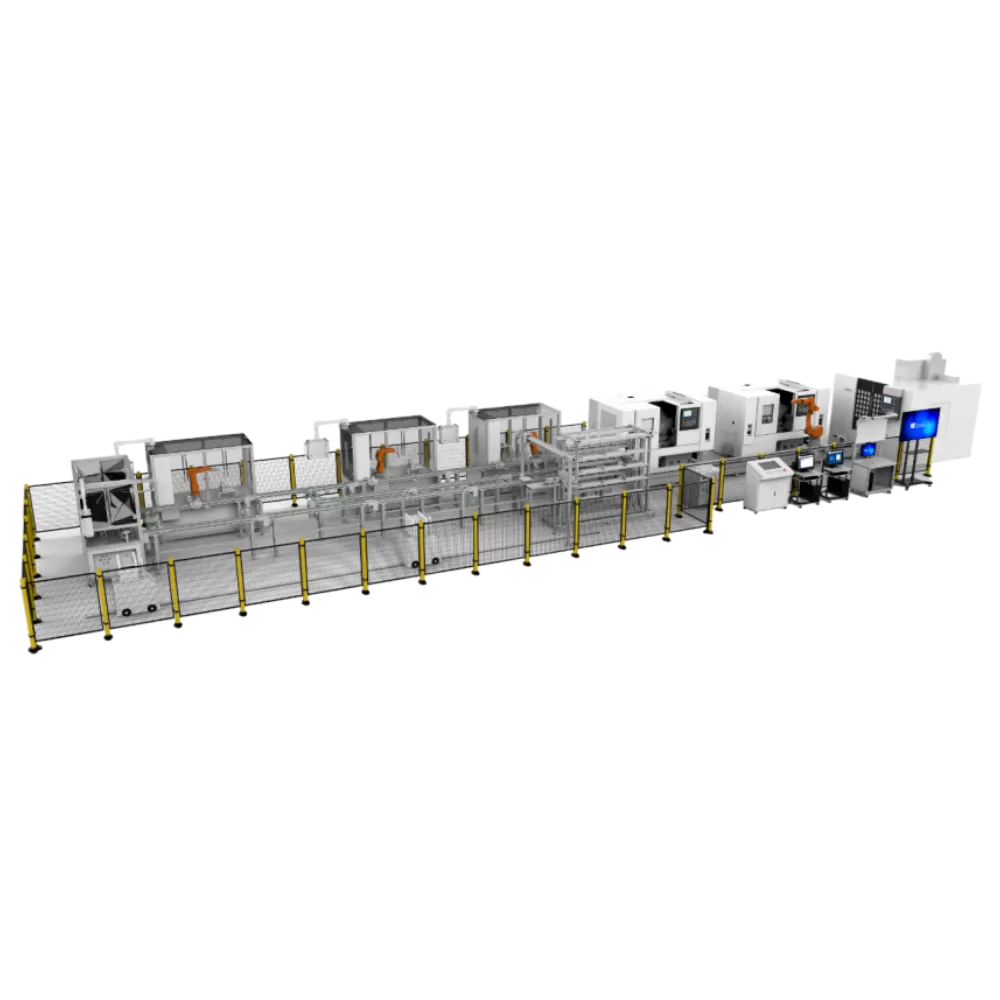

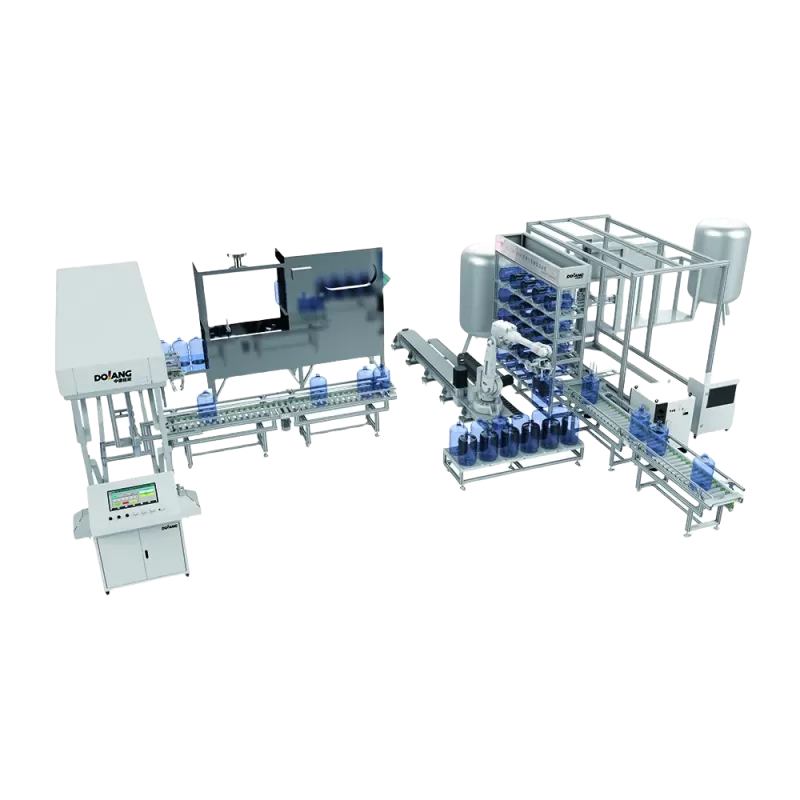

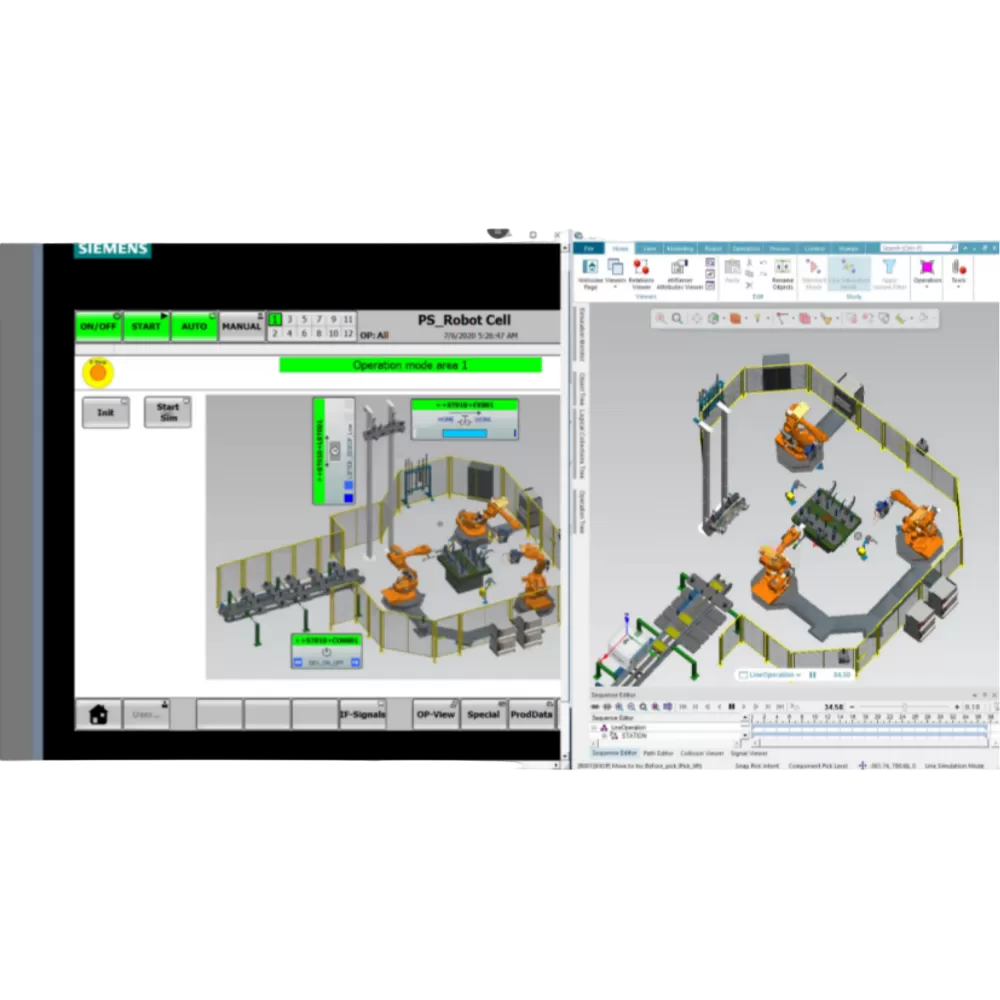

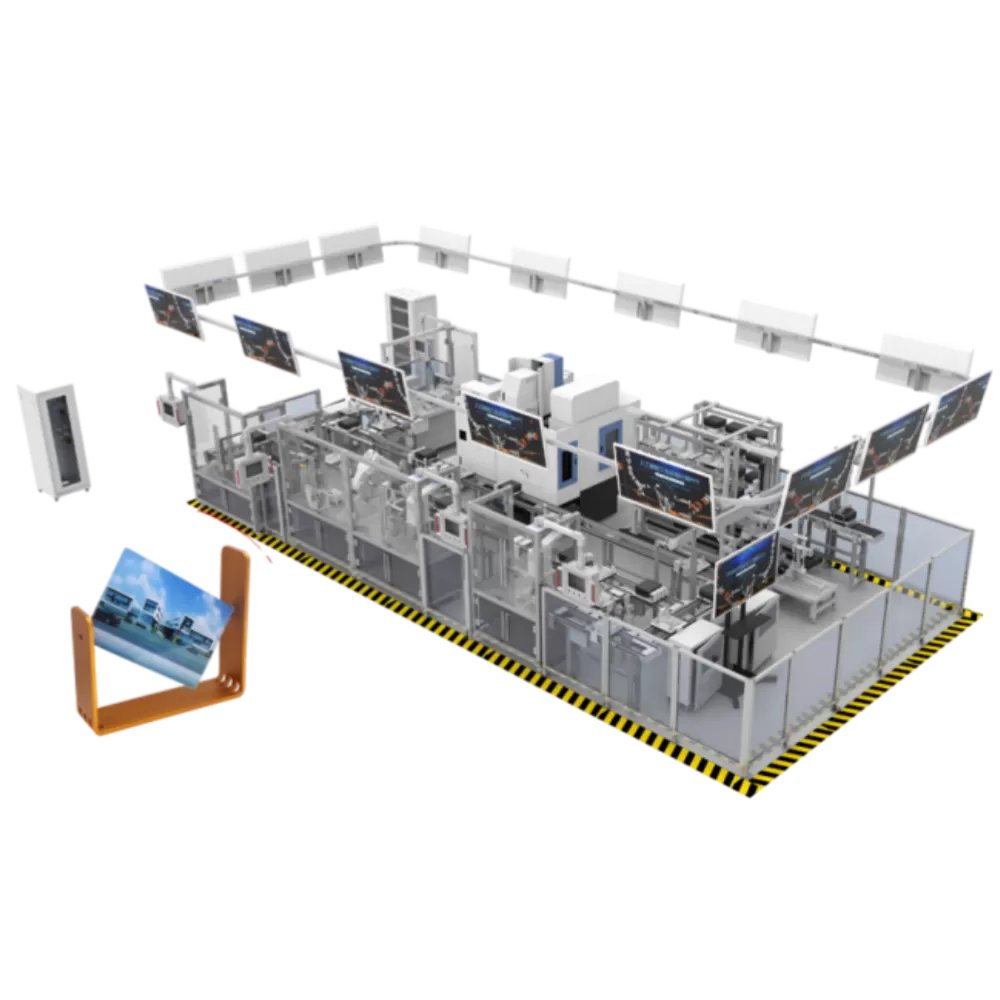

Unlike traditional teaching-oriented laboratories, Dolang Industry solutions emphasize practical application, system operation, and industry workflow understanding, helping institutions build training environments that are closer to real production and engineering scenarios. By integrating real industrial technologies, processes, and application scenarios into teaching environments, Dolang Industry helps institutions cultivate practical, job-ready technical talent.

Industry–Education Integration Based on Real Application Scenarios

Dolang Industry develops industry-oriented training solutions based on actual industrial practices rather than abstract teaching models.

Our systems are designed by combining:

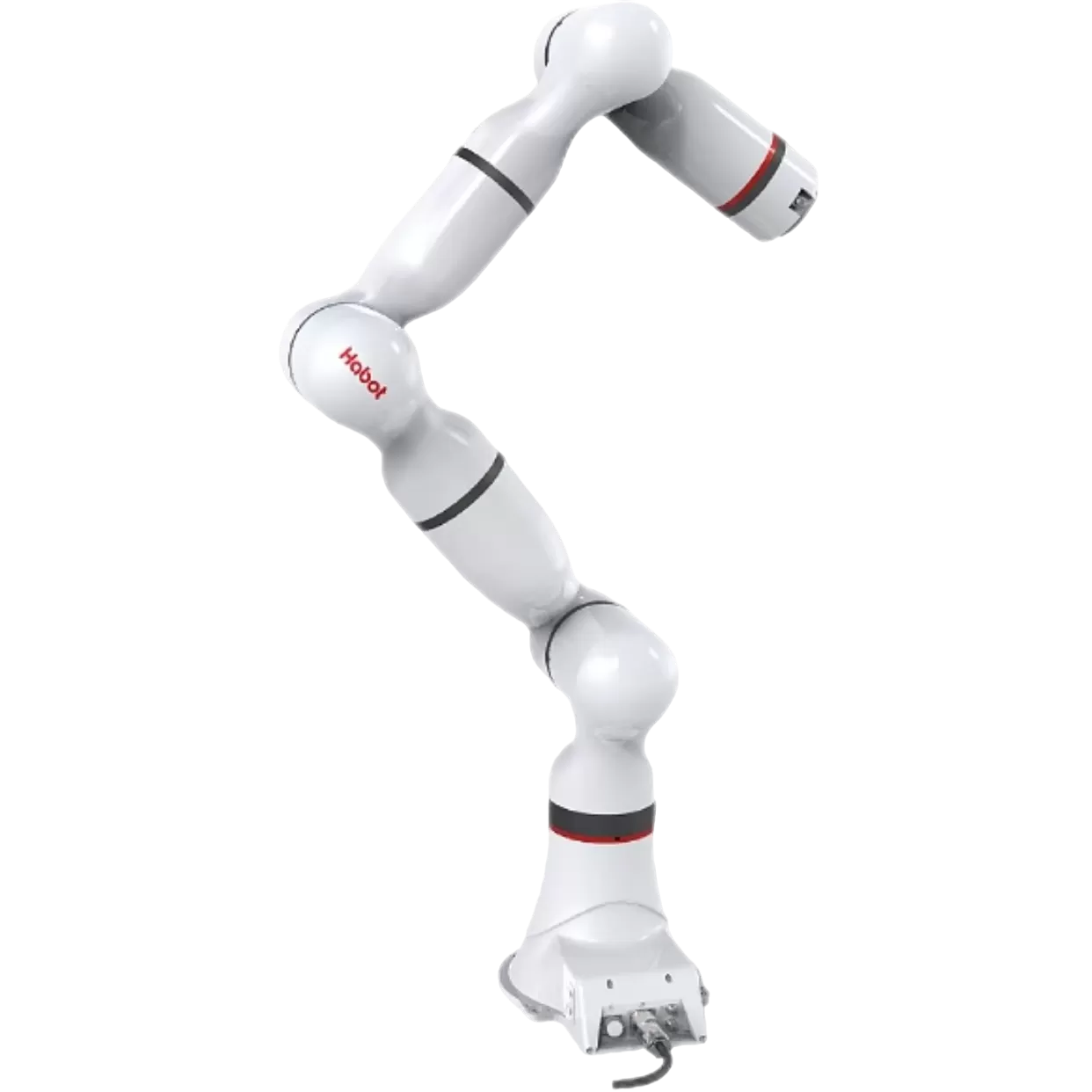

● Typical industry processes and technical standards

● Teaching objectives and curriculum structure

● Skill requirements for applied engineering and technical positions

This approach helps institutions implement industry–education integration projects that are practical, teachable, and sustainable.

Typical application directions include:

● Industry-oriented training laboratories

● Applied engineering and technical training centers

● School–enterprise cooperation training bases

● Pre-employment and skills upgrading platforms

These solutions are widely used by universities, vocational colleges, and technical institutes seeking to improve graduates’ practical competence and job readiness.

Why Choose Dolang Industry

Dolang Industry recognizes that different institutions have different teaching goals, student levels, and space conditions.

We provide customized industry training solutions, including:

● Training system configuration based on industry direction

● Laboratory and training center layout planning

● Equipment selection aligned with teaching and application needs

● Support for curriculum implementation and practical teaching

As an experienced technical training equipment supplier, Dolang Industry focuses on delivering solutions that can be effectively used in daily teaching, not just demonstrated.

Planning an Industry-Oriented Training Project?

Whether you are planning a new industry-oriented laboratory, upgrading an existing training center, or developing a school–enterprise cooperation project, early-stage consultation can significantly improve project outcomes.

Dolang Industry supports institutions with solution planning, equipment selection, and project evaluation, helping you make informed decisions before procurement. Contact Dolang Industry for Project Consultation.